Anaheim, CA — ConMet, a leading global provider of transformative technologies for commercial trucks and trailers, is set to showcase its latest innovations at ACT Expo 2023 this week in Anaheim, CA.

Among the exciting technologies being displayed at ConMet booth #5382, the company’s eMobility business unit will unveil the latest additions to its expanding electrification product line and more.

“Our commitment to electrifying the industry began with our first innovation, the PreSet Plus® eHub™ system, which has paved the way for the development of additional electrification solutions at the wheel end,” said Marc Trahand, Vice President and General Manager of ConMet eMobility. “By drawing on our experience and expertise, and listening to the needs of the fleets, we continue to push forward with new and exciting technologies. So today, we are thrilled to introduce our latest in-wheel electric solutions as part of our nMotion™ product line.”

The nMotion line is comprised of products that feature in-wheel electric power generation systems, as well as additional electrified solutions that enable lower emissions and increased vehicle performance. ACT Expo attendees will have the opportunity for a deep dive into the latest nMotion innovations at ConMet booth #5382, including:

nMotion TR 160-45 powered by PreSet Plus eHub technology

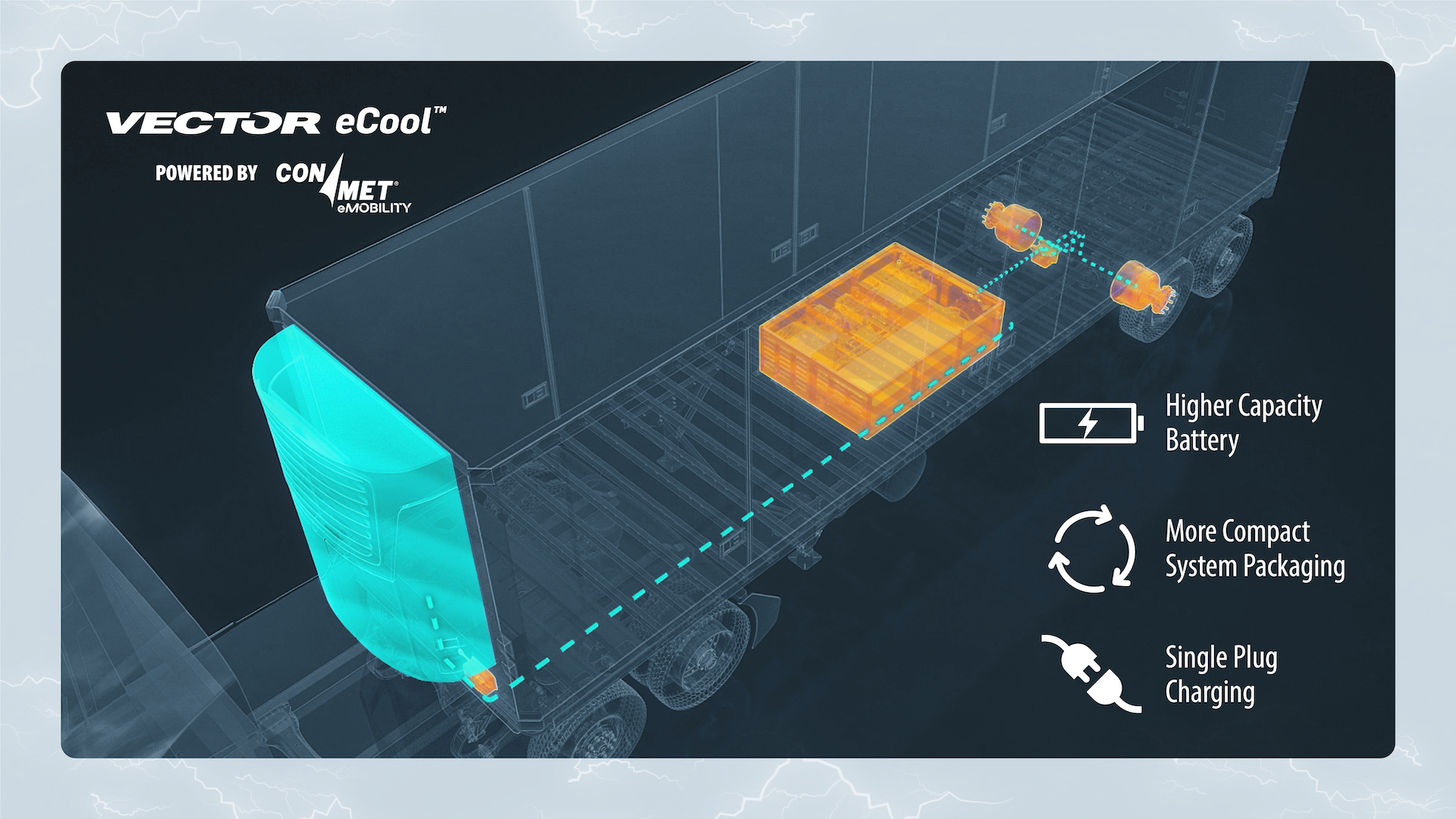

Generation 2 of this advanced system still pairs ConMet eMobility’s eHub technology with a Carrier Transicold Vector TRU to enable zero-emission refrigeration. However, the second-generation system offers several exciting upgrades that enhance performance while simplifying installation, operation, and maintenance.

Designed for applications with higher power generation needs, such as foodservice or grocery delivery, the system is capable of generating an impressive 160kW peak power per axle. Also, the nMotion TR 160-45 comes with a larger capacity battery than its first-generation counterpart, without adding to the overall weight of the system. The 45-kWh option boasts a more compact package with simplified enclosures for easier installation and servicing. In addition, the system now features single-plug charging, only requiring a simple 480 volt 3-phase shore power connection capable of sending energy to the TRU while simultaneously charging the system’s battery.

“We’ve had tremendous success with our initial customers, and we’re excited to continue strengthening our partnerships to bring this technology to more fleets,” Trahand continued. “ACT Expo attendees can visit our commercial partner, Carrier Transicold, and check out the whole system installed on a trailer at booth #6794.”

Carrier Transicold is now accepting orders for Vector eCool TRUs powered by ConMet eMobility’s next-generation nMotion TR 160-45, with first deliveries expected in early 2024.

nMotion TR 20-45 in-wheel electric generator

When paired with ConMet eMobility’s energy management technology and an electric TRU, the nMotion TR 20-45 in-wheel electric generator can also enable zero-emission refrigeration. With peak power of 20 kW per axle, the system is designed for fleets with lower power needs, such as longer over-the-road applications or those with charging available during stops. The flexibility of the outboard-mounted motor allows it to be applied to any brake type including air disc brakes, as well as a range of axle types and trailer lengths.

nMotion RH electronic wheel hub disconnect technology

ConMet eMobility’s nMotion RH electronic wheel hub disconnect technology, when incorporated in an electric drive axle, enables 6×4 to 6×2 conversion via electronic switch or automated by speed via software controls. This new technology helps to extend EV vehicle battery range when applied at highway speeds and can also be used for easy transport of new tractors.

See the full lineup of transformative technologies from ConMet at ACT Expo

All of ConMet’s business units are dedicated to designing products and services that meet the unique needs of the commercial vehicle industry. The organization’s focus on creating better products, processes, and technology revolutionize the way their customers operate and take care of their vehicles. Some of the other innovations that will be on display at ACT Expo include:

ConMet wheel end innovations

- ConMet’s proprietary PreSet® Plus hub assemblies

- The new PreSet Plus efficiency package

- Corrosion resistant flat brake rotor

Castings capabilities

- Lightweight aluminum and specialty iron castings

Plastic components offerings

- Interior and exterior large scale molded plastics

ConMet Digital telematics suite

- PreSet Plus SmartHub™, SmartTrack™ asset management, and SmartAir™ TPMS

- ConMet Digital online dashboard upgrades

- The new ConMet Digital Driver App

Don’t miss ConMet’s full array of innovations during ACT Expo, May 1-4 at the Anaheim Convention Center, booth #5382.

About ACT Expo

For more than a decade, ACT Expo has been the premier annual event showcasing the latest technologies, fuels, services, and vehicles driving the transition to low- and zero-emission transportation solutions. Featuring numerous product debuts and major industry announcements, ACT Expo provides a unique opportunity to network with the most influential thought leaders and progressive fleets in commercial transportation.

About ConMet

ConMet, a division of Amsted Industries, is a leading global supplier of wheel hubs, aluminum castings, and structural plastics to original equipment manufacturers and aftermarket channels in the commercial vehicle industry. Founded in 1964, ConMet innovation has been critical in designing, engineering, and manufacturing revolutionary technologies for trucks and trailers. Today, ConMet products are standard equipment on most heavy-duty vehicles in North America and have a growing footprint worldwide.

ConMet eMobility was established in 2020 to address the needs and challenges of clean energy technology. The growing team has years of experience in electrical engineering, system controls, battery science, and more. Together with the unmatched wheel end expertise and support of ConMet, ConMet eMobility is enabling the development of zero-emission commercial vehicles, capturing and regenerating the kinetic energy that would otherwise go wasted.